It measures and records the width of the pressure zone in real time at multiple points along the surface of the rollers, delivering results with unprecedented speed, precision, and repeatability. Compared to previous solutions, the new Sigma-Nip® not only ensures greater accuracy but is also capable of handling higher pressure levels, thus expanding the possibilities of applications. Sigma-Nip® represents a true revolution in industrial quality control.

For the first time, technicians can measure roller pressure profiles and verify their alignment accurately, quickly, and cost-effectively.

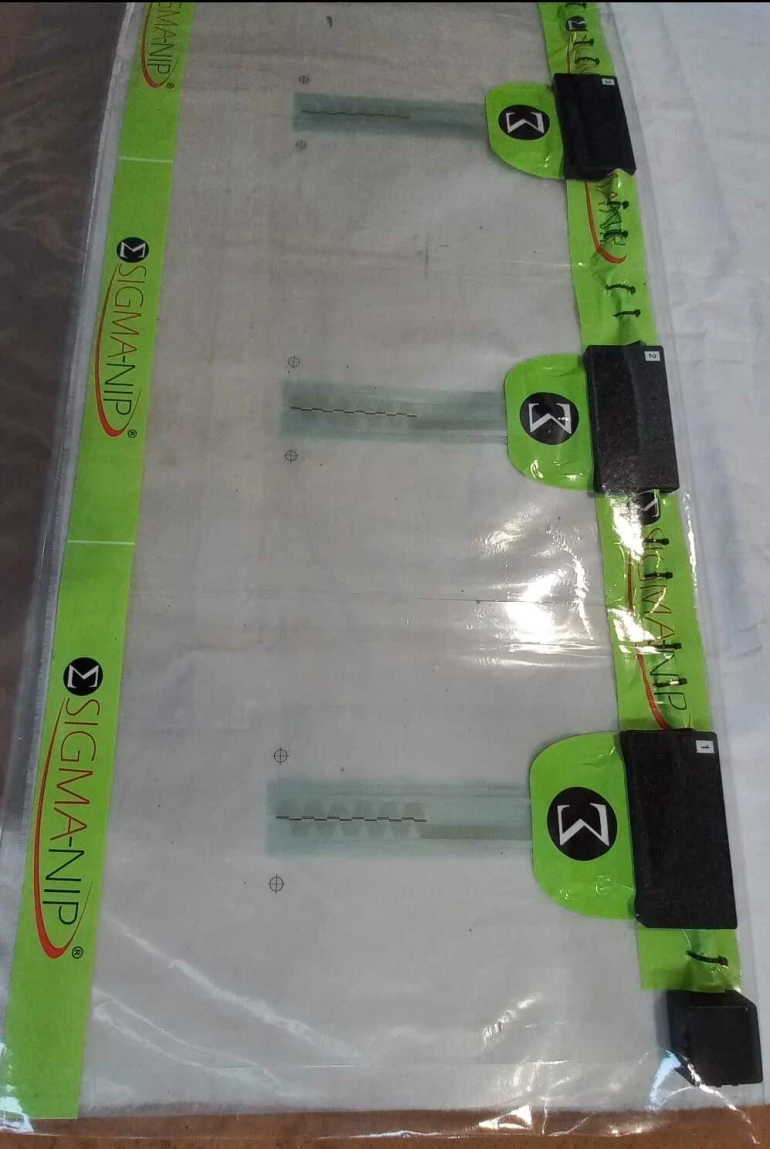

The system consists of an array of thin-film resistive pressure transducers mounted on a flexible support.

By inserting the support between the rollers, the sensors detect the pressure distribution. The dedicated Windows-based software processes the data in real time, transforming it into intuitive and easy-to-interpret graphics. With Sigma-Nip®, contact pressure monitoring becomes simple, precise, and immediate.

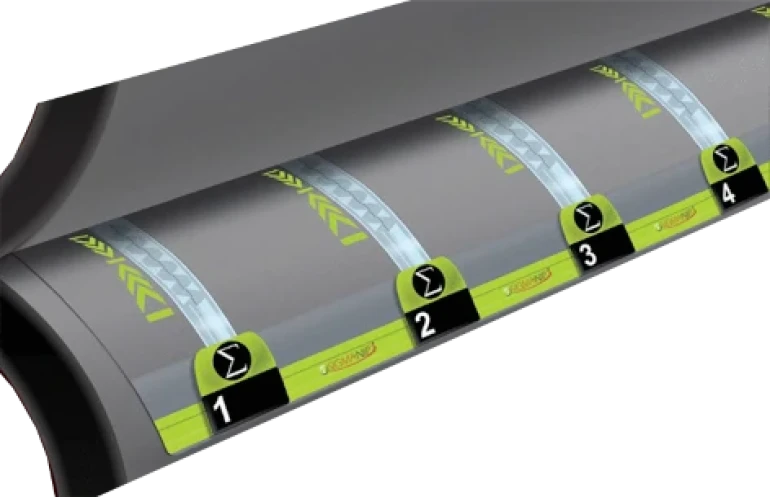

Sigma-Nip® is composed of a series of advanced sensors positioned between two contacting rollers.

As soon as the rollers are closed, the system begins to precisely detect the width of the contact zone (nip), allowing instant verification of roller alignment and the level of pressure applied.

Thanks to its real-time technology, Sigma-Nip® allows immediate adjustments to be made while the sensor is still in the closed (non-rotating) nip.

This approach provides unprecedented flexibility, speed, and control in roller monitoring and calibration.

Ideal for both routine maintenance and installation, the system is designed to be easily operated by a single person, allowing for quick removal of the rollers from the surface.

The standard version is ideal for applications on large rolls or requiring high-amplitude measurement

Benefits

- Its modular and portable design connects instantly to the USB port of any standard Windows laptop, making setup quick and hassle-free

- Optimize roller performance and significantly extend blanket life, reducing maintenance costs and increasing production efficiency.

- Sigma-Nip® is able to detect contact profiles in the transverse direction of the machine with unprecedented precisionDurability and reliability, the sensor withstands repeated high pressure, conforms perfectly to curved surfaces, and tolerates daily exposure to grease, liquids, and inks

Made in Italy

Made in Italy