Tactilus® for Packaging provides precise pressure measurement across products, packaging materials, and handling machinery throughout the production and logistics chain.

Real-time data allows engineers to identify areas of high stress or vulnerability, optimize material usage, and improve packaging designs to reduce the risk of damage during storage and transport.

Tactilus® is ideal for fragile consumer goods, industrial products, and high-volume shipping operations, where ensuring product integrity is critical. By monitoring interactions between packaging materials and machinery, the system supports quality control, process optimization, and efficiency improvements across the supply chain.

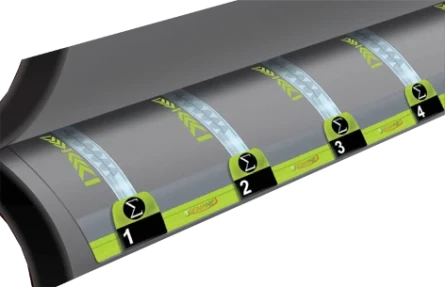

The modular and robust design enables reliable performance in diverse environments, from high-speed production lines to complex logistics operations. By providing actionable insights into pressure distribution and contact forces, Tactilus® helps manufacturers reduce waste, enhance durability, and ensure products reach end-users safely and intact.

Made in Italy

Made in Italy