Tactilus® for Material Production delivers precise pressure measurement across raw materials, forming tools, and production equipment throughout the entire manufacturing workflow.

Real-time data enables engineers to detect areas of excessive stress, irregular material behavior, or equipment misalignment, supporting better control over material properties and processing conditions.

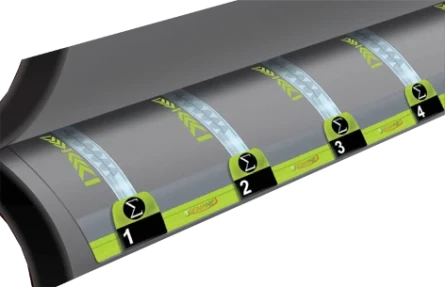

By monitoring interactions between materials and machinery, the system strengthens quality assurance, process stability, and operational efficiency on the production line. Its modular and robust design ensures reliable performance in demanding environments—from high-temperature forming operations to continuous, high-volume production lines.

By providing actionable insights into pressure distribution and contact forces, Tactilus® helps manufacturers reduce waste, improve material reliability, and ensure final products meet stringent industry standards.

Made in Italy

Made in Italy