Industrial

Advanced Solutions for Pressure Analysis in Production Processes

In today’s industrial environment, precision, control, and reliability are essential to ensure quality, efficiency, and operational continuity.

Our tactile pressure-mapping systems represent an advanced solution for accurately monitoring and analyzing the forces exerted between mating surfaces during production, assembly, and testing.

Tactilus® sensors, individually calibrated and engineered for durability, flexibility, and resistance to electromagnetic interference, enable real-time detection of imbalances or anomalies in pressure distribution. Our software platform converts the collected data into intuitive 2D and 3D visualizations, providing crucial insights to help optimize processes and reduce the need for repeated testing.

Compatible with Windows systems and equipped with a USB connection, the system integrates seamlessly into even the most complex industrial environments, helping prevent errors, improve product quality, and minimize downtime.

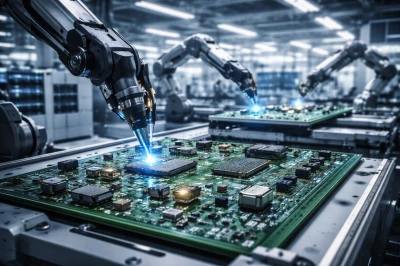

From heavy industry to microelectronics, our solutions adapt to a wide variety of applications, supporting engineers and technicians in meeting the highest production standards. With Tactilus® tactile technology, every detail counts—and every contact is an opportunity for improvement.

Precision and reliability are essential in the industrial sector.

Our systems provide a wide range of pressure mapping solutions tailored for real-time monitoring and diagnostics of systems, presses, mechanical couplings, and other critical surfaces.

Industrial Application Sectors

Tactilus® is an advanced sensor system designed to accurately detect pressure distribution exerted by passengers inside vehicles.

Tactilus® for Electronics delivers high-precision pressure monitoring for delicate components, assemblies, and testing equipment.

Enhance comfort, safety, and durability across all vehicles.

Tactilus® for Transportation provides advanced pressure measurement solutions for cars and various types of transport.

Enhance product quality and optimize manufacturing processes

Made in Italy

Made in Italy