For the first time, technicians can measure roller pressure profiles and verify their alignment accurately, quickly, and cost-effectively.

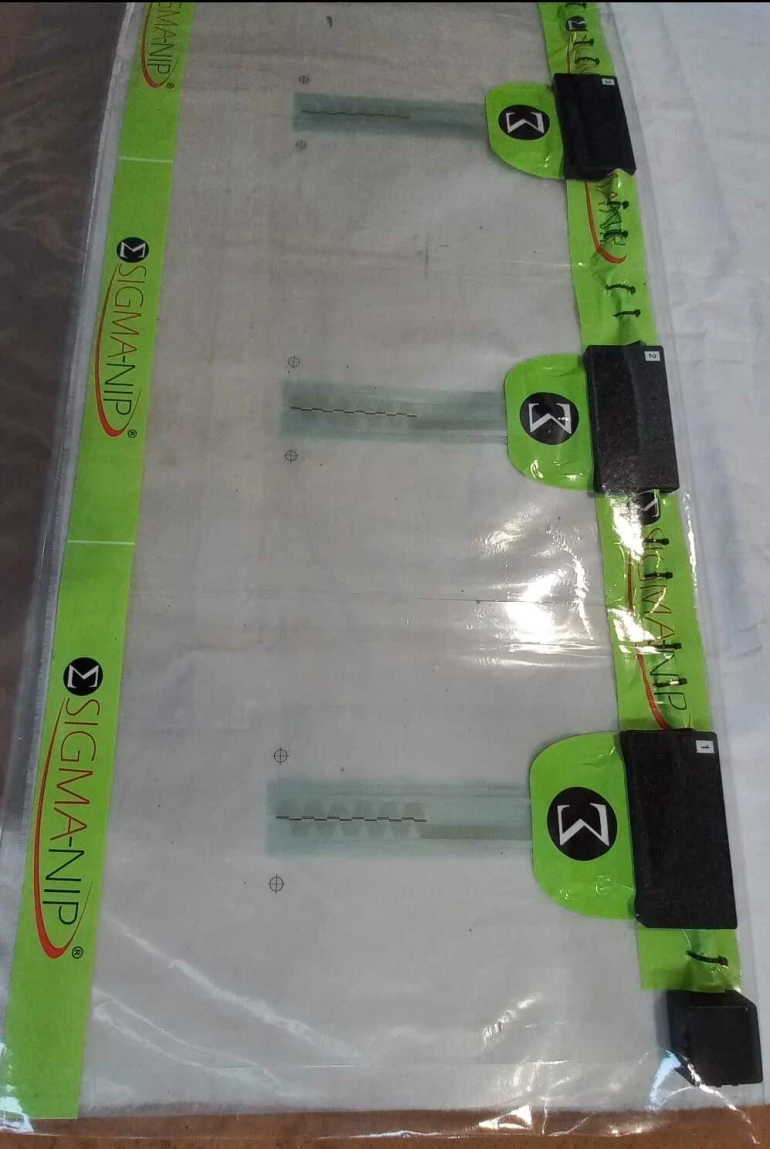

The system consists of an array of thin-film resistive pressure transducers mounted on a flexible support.

By inserting the support between the rollers, the sensors detect the pressure distribution. The dedicated Windows-based software processes the data in real time, transforming it into intuitive and easy-to-interpret graphics. With Sigma-Nip®, contact pressure monitoring becomes simple, precise, and immediate.

Sigma-Nip® is composed of a series of advanced sensors positioned between two contacting rollers.

As soon as the rollers are closed, the system begins to precisely detect the width of the contact zone (nip), allowing instant verification of roller alignment and the level of pressure applied.

Thanks to its real-time technology, Sigma-Nip® allows immediate adjustments to be made while the sensor is still in the closed (non-rotating) nip.

This approach provides unprecedented flexibility, speed, and control in roller monitoring and calibration.

Sigma-Nip® is a complete system designed to quickly and accurately detect pressure marks between rollers.

Ideal for both routine maintenance and installation, the system is designed to be easily operated by a single person, allowing for quick removal of the rollers from the surface.

Proper alignment and pressure balance between the rollers is essential to ensure optimal print quality and effective ribbon control. Evenly loaded rollers dramatically reduce the risk of ribbon breaks, sheet shifting, wrinkles, or unwanted creases.

Through simple routine testing, Sigma-Nip® allows operators to optimize roller performance and significantly extend blanket life, reducing maintenance costs and increasing production efficiency.

Using sophisticated mathematical algorithms, Sigma-Nip® is able to detect contact profiles in the transverse direction of the machine with unprecedented precision. Each sensor is individually calibrated, serialized, and assembled with the utmost care, adhering to extremely tight tolerances.

Two solutions, one excellent technology: Sigma-Nip® Standard and Sigma-Nip® Mini

Sigma-Nip® is available in two versions to meet every application need:

the Standard version, ideal for applications on large rolls or requiring high-amplitude measurement, and the Mini version, designed for smaller spaces and smaller contact surfaces, without sacrificing the precision and reliability typical of the Sigma-Nip® system.

Standard Sigma-Nip

| Active Sensor Area | 8.4 in (21.3 cm) |

| Sensor Thickness | 15 mils (0.381 mm) |

| Operating Temperature Range | from 0 to 250°F (da – 17.7 a 121°C) |

| Resolution | 0.05 in (0.13 cm) |

| NIP Bandwidth Range | From 0.15 to 8.4 in (da 0.38 a 21.3 cm) |

| Minimum Pressure | 40 PSI (2.8kg/cm2) |

| Maximum Pressure | 10,000 PSI (703 kg/cm2) |

| Maximum Exposure Time | 300 sec |

| Detection Points | 168 |

| Substrate Material | PET |

Mini Sigma-Nip

| Active Sensor Area | 4.21 in (10.7 cm) |

| Sensor Thickness | 5 mils (0.381 mm) |

| Operating Temperature Range | From 0 to 250°F (da -17.7 a 121°C) |

| Resolution | 0.02 in (0.5 mm) |

| NIP Bandwidth Range | From 0.06 to 4.21 in (da 0.15 a 10.7 cm) |

| Minimum Pressure | 40 PSI (2.8 kg/cm2) |

| Maximum Pressure | 10,000 PSI (703 kg/cm2) |

| Maximum Exposure Time | 300 sec |

| Detection Points | 168 |

| Substrate Material | PET |

Both versions use individually calibrated sensors and advanced software to provide real-time analysis, enabling rapid adjustments and ensuring accurate quality control, both for routine maintenance and new system installations.

Whether for large industrial systems or more compact applications, Sigma-Nip® always provides safe, fast, and highly accurate pressure measurement.

Made in Italy

Made in Italy